CHRISTMAS TREE (IN OIL INDUSTRY):

The energy sources of the world are either renewable or non-renewable energy sources. Petroleum is a non-renewable energy source and during extraction, crude oil found underground is usually mixed with water, sand, salt and natural gas. As it is extracted, the pressure of these different substances must be kept at just the right levels. This is done by turning valves on and off at the surface level. These valves are often green in colour and the small dials are red, much like the pine trees decorated at Christmas time, this assembly is often referred to as a Christmas tree.

The energy sources of the world are either renewable or non-renewable energy sources. Petroleum is a non-renewable energy source and during extraction, crude oil found underground is usually mixed with water, sand, salt and natural gas. As it is extracted, the pressure of these different substances must be kept at just the right levels. This is done by turning valves on and off at the surface level. These valves are often green in colour and the small dials are red, much like the pine trees decorated at Christmas time, this assembly is often referred to as a Christmas tree.

The words ‘Christmas Tree’ and ‘Wellhead’ are used interchangeably at times; however, a wellhead and Christmas tree are entirely seperate pieces of equipment. A wellhead must be present in order to utilize a Christmas tree and is used without a Christmas tree during drilling operations. Producing surface wells that require pumps (pump jacks, nodding donkeys, etc.) frequently do not utilize any tree due to no pressure containment requirement.

Tree complexity has increased over the last few decades. They are frequently manufactured from blocks of steel containing multiple valves rather than made from multiple flanged valves.

The primary function of a tree is to control the flow into or out of the well, usually oil or gas. A tree often provides numerous additional functions including chemical injection points, well intervention means, pressure relief means (such as annulus vent), tree and well monitoring points (such as pressure, temperature, corrosion, erosion, sand detection, flow rate, flow composition, valve and choke position feedback, connection points for devices such as Down Hole Pressure And Temperature Transducer (DHPT).

In oil and gas extraction, a Christmas tree, or

‘tree’ (not ‘wellhead’ as sometimes incorrectly mentioned), is an assembly of

valves, spools and fittings used for oil wells, gas wells, water disposal

wells, water injection wells, gas injection wells, condensate wells and other

types of wells. It was named as Christmas tree due to its crude resemblance to

this decorated tree.

Christmas trees are used in both subsea and

surface wells. Commonly, there are two types of tree – subsea tree, and surface

tree.

Note

that a Christmas tree isn’t the

same equipment as wellhead. They are different separate pieces of equipment.

The Christmas tree is installed on top of wellhead. A well head can be used

without a Christmas tree during drilling operations. Wells being produced with

the rod pumps (nodding donkeys, pump jacks, etc.) frequently don’t utilize any

tree due to no pressure-containment requirement.

Note

that a Christmas tree isn’t the

same equipment as wellhead. They are different separate pieces of equipment.

The Christmas tree is installed on top of wellhead. A well head can be used

without a Christmas tree during drilling operations. Wells being produced with

the rod pumps (nodding donkeys, pump jacks, etc.) frequently don’t utilize any

tree due to no pressure-containment requirement.THE STRUCTURE OF A CHRISTMAS TREE:

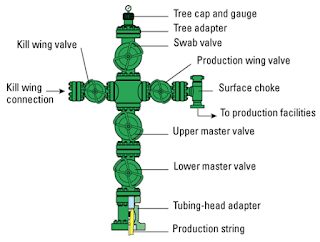

Two lower valves are called master valves

(upper and lower respectively) as they lie in the flow path that well fluids

must take to come to surface. Lower master valve is often manually operated,

while the upper master valve is normally hydraulically actuated.

Two lower valves are called master valves

(upper and lower respectively) as they lie in the flow path that well fluids

must take to come to surface. Lower master valve is often manually operated,

while the upper master valve is normally hydraulically actuated.

• The right hand valve is often known as

production wing valve or flow wing valve, because it is in the flow path that

the hydrocarbons take to production facilities.

• The left hand valve is called the kill wing

valve. It is mainly used for injection of fluids like corrosion inhibitors or

methanol to avert hydrate formation.

• The left hand valve is called the kill wing

valve. It is mainly used for injection of fluids like corrosion inhibitors or

methanol to avert hydrate formation.

• The valve at the top is known as the swab

valve and lies in the path used for well interventions such as wireline and

coiled tubing.

• A choke is a device either stationary or

adjustable. It is used to control the gas flow (also, volume), or create downstream

pressure (also, back pressure).

Shown already on this

Christmas Tree Diagram, there are five valves. The Kill Wing valve, the Swab

valve, the production wing valve, the upper master valve and lower master

valve. When the operator, well, and facilities are ready to produce and receive

oil or gas, valves are opened and the release of the formation fluids is allowed

to flow into and through a pipeline. It is important to understand where these

valves are located and what role they play in getting gas from the well bore to

the customer.

RECOMMENDED STANDARDS FOR CHRISTMAS TREE:

API 6A: Specification for Wellhead and Christmas Tree Equipment .

(You can contact me on how to get a copy if you need it.)

CHRISTMAS TREE PARTS DEFINED:

•The two lower valves are

called the master valves (upper and lower respectively) because they lie in the

flow path, which well fluids must take to get to surface.

•The lower master valve will

normally be manually operated, while the upper master valve is often

hydraulically actuated.

•Hydraulic tree wing valves

are usually built to be fail safe closed, meaning they require active hydraulic

pressure to stay open.

•The right hand valve is often

called the flow wing valve or the production wing valve, because it is in the

flow path the hydrocarbons take to production facilities.

•The left hand valve is often

called the kill wing valve. It is primarily used for injection of fluids such

as corrosion inhibitors or methanol to prevent hydrate formation.

•The valve at the top is

called the swab valve and lies in the path used for well interventions like

wireline and coiled tubing.

A ‘Choke’ is a device, either

stationary or adjustable, used to:

•control

the gas flow, also known as volume

•or create

downstream pressure, also known as back pressure

FUNCTION OF A CHRISTMS

TREE:

The main function of a Christmas tree is to control the oil

and gas flow out of the well. It may also be used to control the injection of

gas or water into the non-producing well so as to improve production rates of

oil from other wells. When the well and facilities are all set to produce and

receive oil or gas, the tree valves are opened and the formation fluids are

enabled to go through a flow line. Then a processing facility, storage depot

and/ or other pipelines lead to a refinery or distribution center for gas. The

flow lines on subsea wells often lead to a fixed or floating production

platform or to a storage ship, known as floating processing unit (FPU), a

floating storage offloading vessel (FSO), a floating production, storage and

offloading vessel (FPSO).

A Christmas tress often provides a number of additional functions, including well

intervention means, pressure relief means, chemical injection points,

monitoring points (pressure, temperature, erosion, corrosion, sand detection,

flow composition, flow rate, valve, choke position feedback, etc.), and

connection points for such devices as down hole pressure and temperature

transducers (DHPT).

A tree may also be used to

control the injection of gas or water injection application on a producing or

non-producing well in order to sustain economic "production" volumes

of gas from other well(s) in the area (field); although injection of chemicals

or alcohols or oil distillates to prevent and or solve production problems (such

as blockages) may be used in producing wells.

The control system attached to

the tree controls the downhole safety valve (SCSSV, DHSV, SSSV) while the tree

acts as an attachment and conduit means of the control system to the downhole

safety valve.

Onshore drilling is used for underground oil reservoirs anywhere on dry

land. Drilling on land generally requires relatively low investments and entails

fewer risks. Once the crude oil is extracted from the ground, it is taken to

gathering centres where the water, sand and salt are removed.

While there, natural gas is also separated from the crude oil and then sent

to a booster station. The oil is then

pumped to storage tanks before being sent to either a refinery for proper

processing or to oil tankers for shipment elsewhere.

Offshore drilling is used to extract oil deposits buried under the ocean

floor. Offshore drilling rigs are installed,

operated and serviced on large platforms built out in the ocean. These platforms can either float or sit on

tall ‘legs’ that touch the seabed. In this way, the offshore rig is able to

remain stable and resist waves, wind and, in colder regions, floating chunks of

ice. Due to its difficulty, offshore drilling consumes more than 65% of planned

investments even before oil is extracted, increasing the risk of financial

losses, especially if wells come up dry!

Exploration activities in finding underground oil

reservoirs and drilling wells are risky, complicated and expensive activities. The cost of drilling an exploratory oil well

can be anything from $1 million to $35 million.

Building and developing a well depends on many

factors: the location of the potential

oil field (if it is on land or under water), the size of the oil field, the

amount of information that is already available and the type of rocks found

underground.

Many oil fields are found in hard-to-reach areas on

land or below deep ocean water. New

technology is helping oil companies reach these oil fields and increase the

amount of oil extracted from the ground.

But in order to pay for new technology, hundreds of millions of dollars in

investments are needed. The average amount of time needed to discover, extract

and market oil is between 3 to 10 years. But oil explorers also need time to

raise the necessary money in order to deal with all the technical challenges.

Much of the time needed depends on the location of

the oil field. An offshore oil field in deep water can take much longer to

discover and test, especially when the sea bottom is thousands of metres below

the surface.

The downstream sector is the part of the oil

industry involved with purifying crude oil and refining it into different

products. It also involves the transportation and marketing of crude oil and

its products. The process through which

crude oil is purified and treated to remove unusable substances is called

REFINING. This process is also used to separate oil into different usable petroleum

products. All this takes place in an oil refinery. All refineries perform three

basic functions: separation, conversion and treatment.

The downstream sector is the part of the oil

industry involved with purifying crude oil and refining it into different

products. It also involves the transportation and marketing of crude oil and

its products. The process through which

crude oil is purified and treated to remove unusable substances is called

REFINING. This process is also used to separate oil into different usable petroleum

products. All this takes place in an oil refinery. All refineries perform three

basic functions: separation, conversion and treatment.

Refining methods are constantly being improved. A variety of complex operations are now used

which have improved their output. Refineries today turn more than half of every

barrel of crude oil into gasoline. One barrel is equal to 159 litres (42 US

gallons). This is a big advance from

only 70 years ago when only 41 litres (11 gallons) of gasoline were produced

from each barrel of crude.

Oil pipelines are made from steel. They usually have an inner diameter of about

10 to 120 cm (about 4 to 48 inches) and can run for hundreds or thousands of

kilometres. Advances in technology are

constantly improving the size and strength of these pipelines. Although

pipelines are less flexible than other forms of transportation, they are the

safest, most efficient and most economical way to move oil. All large modern oil fields have direct

connections to major pipelines. Without

these pipelines, it would be impossible for oil and oil products to reach consumers.

In conclusion, it is noteworthy that the body that

helps to co-ordinate the policies and ensure best practices in the oil industry

is Organization of the Petroleum Exporting Countries (OPEC), and it was

introduced at Baghdad conference held on September 10–14, 1960. The five Founder

Members were: Iran, Iraq, Kuwait, Saudi Arabia and Venezuela. The OPEC logo is

the recognizable symbol of the Organization, and was the result of an

international design competition held in 1969. An Austrian designer, Gertrude

Svoboda, won the competition with her design, which combined the different

letters of the Organization’s name in a rounded design.

No comments:

Post a Comment